Welcome to the ultimate guide on drift eliminators! If you’re looking to enhance the efficiency and performance of your cooling towers while reducing water and chemical treatment costs, you’ve come to the right place. In this comprehensive guide, you will learn everything you need to know about drift eliminators. From understanding how they function in cooling towers to choosing the right one for your business, this guide will upgrade your knowledge and help you make informed decisions.

Key Takeaways:

- Drift eliminators are essential components in cooling towers that prevent the escape of water droplets and protect people and the environment from harmful aerosols.

- They help conserve water, improve water treatment efficiency, and reduce treatment costs.

- Drift eliminators come in various types and designs, such as blade and cellular, and are made from materials like PVC and PP.

- Regular maintenance and replacement of drift eliminators are crucial for optimal performance and to prevent excessive water loss.

- When choosing drift eliminators, consider factors such as adaptability, cost-effectiveness, reliability, certifications, and efficiency.

What are Drift Eliminators and How Do They Work?

Drift eliminators are vital components of cooling towers that play a crucial role in minimizing water loss and preventing water droplets from escaping back into the tower. These components, typically made from materials like PVC, are installed to capture the entrained water droplets and mist before they can be released into the atmosphere.

When the hot, moist air from the cooling tower rises, it carries small droplets of water with it. If left unchecked, these droplets can escape the tower and cause water loss, increased chemical treatment needs, and potential environmental contamination. However, drift eliminators act as a barrier, capturing the water droplets and mist and redirecting them back into the tower, ensuring they do not escape into the surrounding environment.

Drift eliminators are specifically designed to maximize efficiency and minimize pressure loss. They are engineered to create a tortuous path for the air and water droplets, allowing the air to exit the tower while trapping and returning the moisture back into the tower’s water system. This process not only conserves water but also enhances the effectiveness of water treatment systems, reduces chemical treatment costs, and protects the surrounding environment from harmful aerosols.

How Do Drift Eliminators Benefit Cooling Tower Components?

In addition to preventing water loss and environmental contamination, drift eliminators provide several benefits to cooling tower components. By capturing and redirecting the water droplets, drift eliminators help protect sensitive components, such as fans, motors, and fill media, from water damage. This prolongs the lifespan of these components and reduces maintenance requirements.

Furthermore, the use of drift eliminators improves the overall efficiency of the cooling tower. By minimizing water loss, the tower can maintain a consistent water flow rate, ensuring optimal cooling performance. The reduced water loss also means less makeup water is required, resulting in cost savings for businesses.

In summary, drift eliminators are essential components of cooling towers that prevent water loss, protect the environment, and optimize cooling tower performance. By capturing and redirecting water droplets back into the tower, drift eliminators ensure efficient water treatment, reduce chemical treatment costs, and safeguard cooling tower components for long-term functionality.

| Benefits of Drift Eliminators |

|---|

| Minimizes water loss |

| Prevents environmental contamination |

| Protects cooling tower components from water damage |

| Improves cooling tower efficiency |

| Reduces maintenance requirements |

| Reduces chemical treatment costs |

Types of Drift Eliminators

When it comes to drift eliminators, there are various types to choose from, each with its own advantages and applications. Blade-type drift eliminators and cellular drift eliminators are two popular options known for their efficient drift removal capabilities.

Blade-type drift eliminators, as the name suggests, consist of multiple blades arranged in a parallel or staggered configuration. These blades create a tortuous path for the exhaust air, causing the entrained water droplets to collide with the blades and separate from the air stream. This design effectively minimizes the escape of water droplets, ensuring efficient drift removal. Blade-type drift eliminators are especially suitable for cooling towers with high air velocities or where compact size is essential.

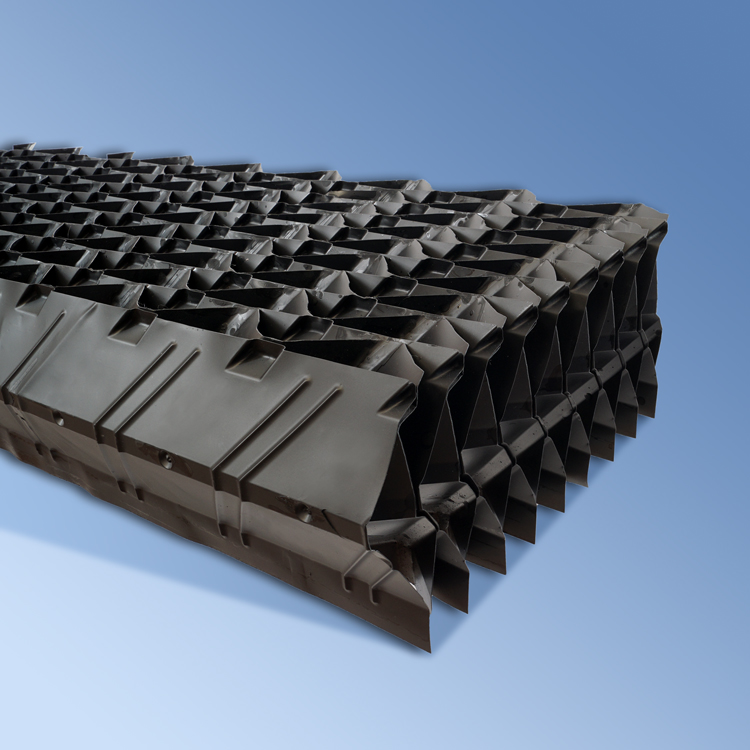

Cellular drift eliminators, on the other hand, feature a honeycomb-like structure with interconnected cells. The design of cellular drift eliminators allows for a larger surface area and higher contact time between the air and water droplets. This increased contact facilitates better separation of water droplets from the air stream, resulting in superior drift removal efficiency. Cellular drift eliminators are commonly used in cooling towers where higher removal efficiencies are required or in applications where the air flow is slower.

Table: Comparison of Blade-Type and Cellular Drift Eliminators

| Features | Blade-Type Drift Eliminators | Cellular Drift Eliminators |

|---|---|---|

| Design | Multiple parallel or staggered blades | Honeycomb-like structure with interconnected cells |

| Efficiency | Efficient drift removal | Superior drift removal efficiency |

| Application | High air velocities, compact size | Higher removal efficiency, slower air flow |

When choosing between blade-type and cellular drift eliminators, it’s important to consider the specific requirements of your cooling tower. Factors such as air velocity, drift removal efficiency, and tower size will influence the optimal choice. Additionally, consulting with a trusted supplier or industry expert can provide valuable insights and guidance in selecting the most suitable drift eliminators for your unique application.

Factors to Consider When Choosing Drift Eliminators

Picking the right drift eliminators for your cooling tower requires careful evaluation of factors such as the tower’s exhaust configuration, whether it operates as a counterflow or crossflow, compliance with industry standards set by organizations like the Cooling Technology Institute (CTI), and the desire for efficient drift removal.

First and foremost, understanding your tower’s exhaust configuration is crucial in selecting the appropriate drift eliminators. Towers that operate as counterflow or crossflow have different requirements when it comes to drift elimination. Counterflow towers require a drift eliminator with a higher removal efficiency to ensure that minimal water droplets escape into the environment. On the other hand, crossflow towers may benefit from drift eliminators that are specifically designed for their unique airflow patterns.

Compliance with industry standards, particularly those set by organizations like the CTI, is another important consideration. These standards ensure that drift eliminators meet specific performance and reliability criteria. Choosing drift eliminators that are CTI certified provides assurance of their effectiveness and adherence to industry best practices.

Efficient Drift Removal

Efficient drift removal is essential to prevent water loss and maintain optimal cooling tower performance. Drift eliminators with high removal efficiency effectively capture and retain water droplets, reducing the risk of aerosol dispersion and potential harm to people and the environment.

When selecting drift eliminators, it is advisable to consider their efficiency ratings. Look for drift eliminators that have been independently tested and verified for their removal efficiency. Manufacturers often provide performance data that can help you compare different products and make an informed decision.

| Material | Removal Efficiency |

|---|---|

| PVC | Up to 99% |

| Polypropylene (PP) | Up to 98% |

| Stainless Steel | Up to 97% |

Table: Comparison of drift eliminators’ removal efficiency based on material used*

*(Note: Removal efficiency percentages are approximate and may vary based on specific product design and operating conditions)

By considering these factors and conducting a thorough evaluation of drift eliminators’ adaptability, cost-effectiveness, reliability, certifications, and efficiency, you can ensure that you select the right drift eliminators for your cooling tower. This will not only enhance the tower’s performance but also contribute to water conservation efforts and reduce chemical treatment costs.

The Importance of Drift Removal Efficiency

Achieving optimal drift removal efficiency is essential to minimize water loss and maintain compliance with environmental regulations. Even a seemingly small improvement, such as reducing drift rate from 0.001% to 0.0005%, can result in substantial reductions in the amount of water entrained in the leaving air stream from the tower’s exhaust.

Water loss through drift can have serious consequences, both environmentally and economically. The entrainment of water droplets in the exhaust air can lead to the dispersion of harmful bacteria, posing health risks to people in the vicinity. Additionally, excessive water loss can disrupt the balance of water treatment in cooling towers, increasing water and chemical treatment costs.

By installing high-efficiency drift eliminators, businesses can effectively minimize water loss and ensure compliance with environmental regulations. These drift eliminators are designed to capture and remove water droplets from the air stream, preventing their release into the environment. This not only protects the surrounding areas but also improves water treatment efficiency and reduces the need for costly water and chemical treatments.

| Benefits of Efficient Drift Removal: |

|---|

| Minimizes water loss |

| Reduces environmental impact |

| Improves water treatment efficiency |

| Decreases water and chemical treatment costs |

When selecting drift eliminators, it is important to consider their efficiency in removing water droplets, as well as other factors such as adaptability to different cooling tower designs, cost-effectiveness, reliability, and certifications. Investing in high-quality drift eliminators ensures long-lasting performance and helps businesses achieve their environmental and operational goals.

Benefits of Using Drift Eliminators

Drift eliminators offer numerous benefits when installed in cooling towers, ranging from enhancing the evaporative cooling process to minimizing maintenance requirements and extending the lifespan of other tower components. These efficient drift eliminators play a crucial role in preventing water loss and ensuring optimal performance in cooling tower systems.

One of the key advantages of using drift eliminators is their ability to enhance the evaporative cooling process. By capturing water droplets entrained in the discharge air stream, drift eliminators help maintain the desired water flow rate within the cooling tower, maximizing the cooling efficiency. This not only improves the overall performance of the tower but also contributes to significant energy savings.

Additionally, drift eliminators help minimize maintenance requirements by preventing the accumulation of water droplets on other tower components. By reducing the potential for corrosion and scaling, drift eliminators help prolong the lifespan of essential tower elements such as fill media and fans. This results in reduced maintenance costs and increased operational reliability.

When it comes to choosing drift eliminators, efficiency is a critical factor to consider. Efficient drift eliminators are designed to minimize water loss and chemical treatment needs, ensuring compliance with environmental regulations and reducing operational costs. By utilizing highly effective drift eliminators, businesses can achieve optimal performance, conserve resources, and promote sustainability.

| Benefits of Using Drift Eliminators: |

|---|

| – Enhance evaporative cooling |

| – Minimize maintenance requirements |

| – Extend lifespan of other tower components |

| – Reduce water and chemical treatment costs |

| – Ensure compliance with environmental regulations |

Efficient Drift Eliminator Types

Drift eliminators are available in various types, each offering its own set of advantages in terms of efficiency. Blade drift eliminators, for example, are designed with angled blades that effectively capture and redirect water droplets away from the airflow. These blade type eliminators are known for their high drift removal efficiency and low pressure drop, making them suitable for a wide range of cooling tower applications.

Cellular drift eliminators, on the other hand, are engineered with a honeycomb structure that enables efficient water droplet capture and drainage. Their design maximizes the surface area available for contact with the air stream, enhancing both drift removal efficiency and airflow performance. Cellular drift eliminators are often preferred in applications where higher efficiency and lower pressure drop are required.

By understanding the benefits and features of different drift eliminator types, businesses can select the most appropriate option to meet their specific cooling tower requirements. Whether it’s the blade type or cellular design, efficient drift eliminators offer reliable performance and significant cost-saving advantages.

Different Materials Used in Drift Eliminators

Drift eliminators are typically constructed using different materials, including PVC sheets, polypropylene (PP), and stainless steel, each offering specific strengths and benefits depending on the application and environment. PVC sheets are widely used due to their affordability and excellent resistance to corrosion, making them suitable for cooling towers in various industries.

Polypropylene (PP) drift eliminators, on the other hand, provide superior chemical resistance and are ideal for applications where exposure to aggressive chemicals is a concern. PP is known for its durability and ability to withstand high temperatures, making it suitable for cooling towers used in demanding industrial processes.

Stainless steel drift eliminators are another option, offering exceptional strength and corrosion resistance. They are often chosen for applications in corrosive environments or where hygiene and cleanliness are paramount, such as food processing or pharmaceutical facilities.

| Material | Strengths | Benefits |

|---|---|---|

| PVC sheets | Affordable, corrosion-resistant | Cost-effective, suitable for various industries |

| Polypropylene (PP) | Chemical-resistant, durable, high temperature resistance | Ideal for aggressive chemical environments |

| Stainless steel | Strong, corrosion-resistant | Suitable for corrosive environments, hygienic applications |

Importance of Regular Maintenance and Replacement

Regular maintenance and timely replacement of drift eliminators are critical to maximizing their effectiveness, minimizing corrosion risks, and ensuring adequate air and water flow rates in your cooling tower. Drift eliminators play a vital role in reducing the escape of water droplets entrained in the discharge air stream, protecting both people and the environment from harmful aerosols and water droplets. To maintain their functionality, drift eliminators should be inspected and cleaned regularly to prevent blockages caused by dust, debris, and biological growth.

Corrosion is a common issue in cooling towers, and deteriorated drift eliminators can contribute to this problem. If drift eliminators become damaged or lose their integrity, they may allow corrosive elements to reach other tower components, leading to accelerated deterioration and potential system failure. By maintaining and replacing drift eliminators as needed, you can prevent corrosion and extend the lifespan of your cooling tower.

Another important factor to consider is the impact of blocked or deteriorated drift eliminators on air and water flow rates. When drift eliminators become clogged or damaged, they can impede the flow of air and water within the cooling tower, reducing the efficiency of the cooling process. Timely maintenance and replacement of drift eliminators ensure that the tower operates at optimal efficiency, enhancing overall performance and minimizing energy consumption.

Regular maintenance and replacement of drift eliminators offer the following benefits:

- Maximized drift removal efficiency, reducing water loss and water treatment costs

- Minimized risk of corrosion and damage to other tower components

- Optimized air and water flow rates, ensuring efficient cooling and energy savings

- Extended lifespan of the cooling tower

By prioritizing regular maintenance and timely replacement of drift eliminators, you can safeguard the performance and longevity of your cooling tower, while also maintaining compliance with environmental regulations and reducing operational costs.

| Maintenance and Replacement | Benefits |

|---|---|

| Regular maintenance |

|

| Timely replacement |

|

Choosing the Right Drift Eliminators for Your Business

To make an informed decision and choose the right drift eliminators for your business, it’s essential to consider factors such as their effectiveness in removing drift, the availability of compatible cooling tower parts and products, lead time for ordering and delivery, and the overall goal of minimizing water loss to the environment. Effective drift removal is crucial for cooling tower efficiency and compliance with environmental regulations. The following factors can help guide you in selecting the most suitable drift eliminators:

- Effectiveness: Look for drift eliminators that have been proven to effectively capture and remove water droplets from the air stream. Consider their design and efficiency in minimizing water loss and preventing aerosol dispersion, as well as their ability to protect people and the environment from harmful contaminants.

- Compatibility: Ensure that the drift eliminators you choose are compatible with your cooling tower’s design and specifications. Check for compatibility with other tower components and the availability of compatible parts and products to ensure seamless integration.

- Lead Time: Consider the lead time required for ordering and delivery of the drift eliminators. Timely availability of these components is crucial to minimize downtime and ensure uninterrupted operation of your cooling tower.

- Environmental Impact: Minimizing water loss to the environment is essential for sustainability and cost-effectiveness. Choose drift eliminators that are designed to efficiently capture and return as much water as possible back into the cooling tower, reducing the need for additional water supply and chemical treatment.

By carefully evaluating these factors, you can select drift eliminators that meet your specific needs and deliver optimal performance for your cooling tower. Remember to consider adaptability, cost-effectiveness, reliability, certifications, and efficiency in your decision-making process. Consulting with trusted industry professionals and suppliers can also provide valuable insights and recommendations to help you make the right choice for your business.

Table: Comparison of Drift Eliminators

| Drift Eliminator Type | Effectiveness | Compatibility | Lead Time | Environmental Impact |

|---|---|---|---|---|

| Blade | High | Compatible with various cooling tower configurations | Short lead time | Efficient water conservation |

| Cellular | Excellent | Compatible with most cooling towers | Varies based on supplier | Optimized water recovery |

| Other types | Depends on specific design | Varies based on cooling tower specifications | Depends on supplier | Varies based on design and materials |

Quote:

“Choosing the right drift eliminators is crucial for achieving optimal performance and efficiency in your cooling tower. By considering factors such as effectiveness, compatibility, lead time, and environmental impact, you can make an informed decision that not only meets your business needs but also contributes to water conservation and environmental sustainability.” – Cooling Tower Expert

Find a Trusted Drift Eliminator Supplier

When it comes to drift eliminators, finding a dedicated supplier with expertise in the field is crucial to ensure you obtain the right material, proper installation, and ongoing support to effectively manage the water entrained in the leaving air and other related challenges. A dedicated supplier will have a deep understanding of drift eliminators and their role in cooling towers, allowing them to recommend the most suitable options for your specific needs.

A trusted supplier will offer a wide range of drift eliminator types, such as cellular and blade, made from materials like PVC and PP. They will provide detailed information on each type, including their unique features and benefits, giving you the knowledge to make an informed decision. Additionally, a reputable supplier will ensure that the drift eliminators they offer are compliant with industry standards and certifications, guaranteeing their quality and performance.

Proper installation is essential for drift eliminators to function effectively. A dedicated supplier will have experienced technicians who can install the drift eliminators correctly, ensuring they are securely in place and properly sealed. They will provide ongoing support to address any issues you may encounter, answer your questions, and offer maintenance advice to maximize the performance and lifespan of your drift eliminators.

To find a trusted drift eliminator supplier, consider their expertise, reputation, and customer reviews. Look for a supplier who offers a comprehensive range of drift eliminators, superior customer service, and a reliable warranty. By partnering with a dedicated supplier, you can have confidence in the quality, performance, and longevity of your drift eliminators, ultimately optimizing the efficiency and effectiveness of your cooling tower.

Table: Drift Eliminator Materials and Characteristics

| Material | Characteristics |

|---|---|

| PVC | Durable, lightweight, resistant to corrosion and chemicals |

| PP | High-temperature resistance, excellent chemical resistance |

Conclusion

In conclusion, drift eliminators play a vital role in maintaining the efficiency and performance of cooling towers in diverse applications. By choosing the appropriate drift eliminators, considering factors like crossflow applications, vertical configuration, surface area, and cost-effectiveness, businesses can maximize the benefits of their cooling systems while minimizing water loss and ensuring compliance with environmental standards.

Drift eliminators are crucial components that prevent the escape of water droplets entrained in the discharge air stream, protecting both people and the environment from aerosols and harmful bacteria. These eliminators help conserve water, improve water treatment efficiency, and reduce water and chemical treatment costs, making them indispensable in cooling tower operations.

With different types and designs available, such as cellular and blade drift eliminators, businesses have options to suit their specific needs. Materials like PVC and polypropylene are commonly used to manufacture drift eliminators, offering durability and corrosion resistance.

Maintenance and regular replacement of drift eliminators are essential to prevent excessive water loss and maintain optimal performance. By selecting drift eliminators that are adaptable, cost-effective, reliable, and certified, businesses can ensure long-term efficiency and compliance with industry standards.

Introduction to Drift Eliminator Design

You may not realize it, but drift eliminators play a crucial role in the efficient operation of cooling towers. They are designed to capture and remove tiny water droplets that are carried along with the exhaust air from the cooling tower. But how do you go about designing effective drift eliminators? This article will provide you with the factors to consider when designing them, and the different types available.

Factors to consider when designing drift eliminators

Several factors should be taken into account when designing drift eliminators for cooling towers:

- Efficiency: The primary goal of a drift eliminator is to remove as many water droplets as possible. The design should optimize droplet capture efficiency while minimizing pressure drop across the eliminators.

- Airflow restriction: While it’s essential to have efficient droplet capture, the design should also consider the airflow restriction caused by the drift eliminators. Balancing these two factors is crucial to ensure proper cooling tower performance.

- Material selection: Drift eliminators are exposed to corrosive water and extreme weather conditions. Choosing the right materials, such as corrosion-resistant plastic or stainless steel, is vital to ensure durability and a long product life.

Different types of drift eliminator designs and their benefits

There are several types of drift eliminators available, including chevron blade, cellular, and bladeless designs. Each type offers unique benefits and is suitable for different cooling tower applications.

- Chevron Blade: This design features a series of chevron-shaped blades that create turbulence, enhancing droplet capture efficiency.

- Cellular: Cellular drift eliminators are made up of interconnected cells that provide a large surface area for droplet capture while minimizing airflow restriction.

- Bladeless: Bladeless drift eliminators use a series of angles and barriers to redirect airflow and capture droplets efficiently.

Choosing the right type of drift eliminator depends on factors such as the cooling tower’s design, airflow requirements, and water quality.

In conclusion, proper drift eliminator design is essential for the efficient operation of cooling towers. By considering factors such as efficiency, airflow restriction, and material selection, you can ensure optimal performance and reduced water loss in your cooling tower system.

Drift Eliminator Design Considerations

Effects of drift loss on the environment and nearby structures

When it comes to drift eliminators, the design is vital in reducing drift loss. Drift loss refers to the small water droplets that are carried outside the cooling tower, and it can have significant consequences on the environment and nearby structures.

Excessive drift loss can lead to water pollution, as these droplets containing chemicals and contaminants can contaminate nearby water bodies. This can have severe ecological implications, especially for aquatic life. Additionally, drift loss can also pose a risk to nearby structures and equipment, as the droplets can cause corrosion and damage over time.

Design considerations for minimizing drift loss

To minimize drift loss, various design considerations need to be taken into account during the drift eliminator design process:

- Fin Density: The density of fins within the drift eliminator affects its efficiency. Higher fin density can effectively capture more water droplets.

- Drift Eliminator Height: The height of the drift eliminator impacts its effectiveness in capturing water droplets. A taller eliminator provides a longer distance for the droplets to settle, reducing drift loss.

- Water Flow Rate: Optimizing the water flow rate through the cooling tower can help prevent excessive drift loss. Proper control of water distribution is crucial in minimizing the amount of water that escapes as drift.

Importance of proper airflow distribution in drift eliminator design

Proper airflow distribution within the cooling tower is vital for effective drift elimination. The design should ensure uniform flow of air through the eliminator, allowing for efficient capture of water droplets.

Without proper airflow distribution, certain areas within the drift eliminator may have reduced air velocity, resulting in compromised drift elimination efficiency. This can lead to increased drift loss and potential environmental and structural issues.

By considering the factors mentioned above and ensuring proper airflow distribution, the design of drift eliminators can be optimized to minimize drift loss, protect the environment, and preserve nearby structures. Effective drift elimination not only ensures regulatory compliance but also promotes sustainable and responsible operation of cooling towers.

Overall, drift eliminator design plays a crucial role in reducing drift loss, protecting the environment, and maintaining the integrity of nearby structures. It is important to prioritize proper design considerations and airflow distribution to achieve optimal performance and minimize the impact of drift loss.

Other Types of Drift Eliminators

When it comes to designing an efficient cooling tower, drift eliminators play a crucial role in preventing the escape of water droplets into the atmosphere. These components are specifically designed to reduce the drift rate and improve the overall performance of the cooling tower. In this article, we will explore other three common types of drift eliminators: baffle type, wave type, and grid type.

Baffle Type Drift Eliminators: Features and benefits

Baffle type drift eliminators are commonly used in industrial cooling towers. These eliminators utilize a series of baffles or vane separators to capture water droplets and redirect them back into the tower. The design of baffle type eliminators ensures maximum removal efficiency and minimal pressure drop. The benefits of using baffle type drift eliminators include reliable performance, low maintenance requirements, and easy installation.

Wave Type Drift Eliminators: Advantages and considerations

Wave type drift eliminators feature a corrugated design that enhances water capture efficiency. The waves in the eliminators help to create a tortuous path, forcing the droplets to change direction and collide with the surface of the eliminator. Wave type eliminators are known for their high drift removal efficiency and low airflow resistance. However, it is important to note that these eliminators may require more regular cleaning and maintenance compared to other types.

Grid Type Drift Eliminators: Design and performance characteristics

Grid type drift eliminators consist of a grid pattern made up of closely spaced bars or fins. These eliminators effectively capture the water droplets as the air passes through the grid. The design allows for high drift removal efficiency while maintaining low pressure drop. Grid type eliminators are often preferred in applications where cleanliness and ease of maintenance are crucial factors. They are also suitable for systems with higher air velocities.

In conclusion, drift eliminators are essential components of cooling towers that prevent the escape of water droplets into the environment. Each type of eliminator offers its own set of features, benefits, and considerations. Choosing the right drift eliminator for your cooling tower requires considering factors such as efficiency, maintenance requirements, and system specifications. By selecting the appropriate drift eliminator, you can ensure optimal performance and minimize water loss in your cooling tower system

Innovations in Drift Eliminator Design

Advanced materials and coatings for enhanced performance

When it comes to drift eliminator design, using advanced materials and coatings can significantly enhance the performance and efficiency of your system. As an engineering professional in the field, you may already be familiar with the importance of drift eliminators in cooling towers and air scrubbers. These components play a crucial role in preventing water droplets from escaping with the exhaust air stream, which can cause a host of problems, including environmental concerns, reduced system efficiency, and increased operating costs.

By incorporating advanced materials and coatings into your drift eliminator design, you can achieve several benefits, such as improved water droplet capture efficiency and increased resistance to corrosion and scaling. Let’s delve deeper into these advantages:

- Improved water droplet capture efficiency: Advanced materials, such as high-performance plastic polymers or fiber-reinforced composites, can provide a higher surface area and greater surface energy for better droplet capture. This ensures that more water droplets are captured and returned to the system, reducing water loss and increasing water conservation efforts.

- Resistance to corrosion and scaling: Traditional drift eliminators are prone to corrosion and scaling due to prolonged exposure to water and harsh operating conditions. However, by incorporating corrosion-resistant materials or applying specialized coatings, you can extend the lifespan of your drift eliminators and minimize maintenance requirements. These advanced materials and coatings can withstand the corrosive effects of water and chemicals, ensuring long-term performance and cost savings.

- Easier maintenance and cleaning: Drift eliminators with advanced materials and coatings can be designed with improved surface characteristics, making them easier to clean and maintain. Smooth surfaces or non-stick coatings can prevent the accumulation of debris and scale, reducing the frequency and effort required for cleaning.

It is important to note that the selection of materials and coatings should be based on the specific operating conditions and requirements of your system. Factors such as temperature, chemical exposure, and airflow patterns should be considered when determining the optimal drift eliminator design for your application.

In conclusion, incorporating advanced materials and coatings into drift eliminator design can greatly enhance the performance and efficiency of your cooling tower or air scrubber system. By improving water droplet capture efficiency and providing resistance to corrosion and scaling, these innovations contribute to water conservation efforts, extend the lifespan of your equipment, and reduce maintenance costs. Always consult with experts in the field to ensure the best possible design for your specific needs.

FAQ

Q: What is the function of drift eliminators in cooling towers?

A: Drift eliminators reduce the escape of water droplets entrained in the discharge air stream of cooling towers. They help protect people and the environment from aerosols and water droplets and prevent the dispersion of harmful bacteria.

Q: How do drift eliminators help conserve water?

A: Drift eliminators minimize water loss by preventing excessive water droplets from escaping the tower. This conservation of water not only helps improve water treatment efficiency but also reduces water and chemical treatment costs.

Q: What are the different types of drift eliminators available?

A: There are various types of drift eliminators, including cellular and blade designs. Each type offers unique features and benefits for different cooling tower applications.

Q: When should drift eliminators be replaced?

A: Drift eliminators should be replaced when they become deteriorated or blocked. This is important to avoid excessive water loss and increased chemical treatment needs.

Q: What factors should be considered when choosing drift eliminators?

A: When selecting drift eliminators, factors such as adaptability, cost-effectiveness, reliability, certifications, and efficiency should be taken into consideration.