Welcome to our comprehensive guide on negative air machines and their significant impact on indoor air quality. In this article, we will explore the important role that negative air machines play in maintaining a healthy and safe environment. We will discuss their functionality, the importance of negative pressure and HEPA filtration, their applications in various industries, and much more. So, let’s dive in and explore the world of negative air machines to understand how they can improve air quality and promote health safety.

- Negative air machines are essential for maintaining air quality in various settings, such as medical facilities, factories, and construction sites.

- These machines create negative air pressure to isolate spaces and prevent the spread of pathogens.

- Filters, including HEPA and ULPA filters, are used in negative air machines to clean the air and remove particles.

- Proper room sealing and electronic pressure monitoring are crucial for effective isolation.

- Air scrubbers are similar to negative air machines but are more suitable for smaller spaces like residences and restaurants.

Understanding Negative Air Machines and Their Functionality

Negative air machines, also referred to as air scrubbers, have been specifically designed to clean and control the air in a work area to ensure a safe environment. These machines play a vital role in maintaining air quality in various settings, such as medical facilities, factories, and construction sites. By creating negative air pressure, negative air machines effectively isolate spaces and prevent the spread of pathogens.

One of the key features of negative air machines is their ability to remove harmful particles from the air. These machines utilize filters, including HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Particulate Air) filters, to capture and trap contaminants, ensuring cleaner and healthier air for occupants. With the ability to remove particles as small as 0.3 microns in size, negative air machines provide superior air cleaning capabilities.

Proper room sealing and electronic pressure monitoring are essential for the effective isolation and operation of negative air machines. By sealing off the work area, these machines prevent contaminated air from escaping and spreading to other parts of the facility. Electronic pressure monitoring allows for real-time monitoring and adjustment of the air pressure, ensuring that the desired level of negative pressure is maintained.

“Negative air machines are a powerful tool in smoke remediation. They can effectively remove harmful particles and gases from the air, improving the air quality and creating a safer environment for occupants.” – Air Quality Expert

While negative air machines are highly effective in larger spaces, air scrubbers are more suitable for smaller areas like residences and restaurants. Both machines utilize similar technologies and filters to remove air pollutants and improve air quality. However, negative air machines are designed for more extensive applications, such as construction sites and medical facilities, where larger volumes of air need to be cleaned and controlled.

| Negative Air Machines | Air Scrubbers |

|---|---|

| Designed for larger spaces | Designed for smaller areas |

| Utilize filters, including HEPA and ULPA filters, for superior air cleaning | Also utilize filters, but may have lower filtration capabilities |

| Create negative air pressure to isolate the work area | Control the air quality within a confined space |

Overall, negative air machines and air scrubbers are important tools in maintaining air quality and ensuring a safe environment. Whether it’s for a construction site, a medical facility, or a residential space, these machines effectively remove air pollutants and improve the overall indoor air quality.

The Importance of Negative Pressure and HEPA Filtration

Negative air machines harness the power of negative pressure and HEPA filtration to efficiently remove airborne contaminants from the surrounding air. These machines play a crucial role in maintaining clean and safe environments, particularly in settings where air quality is of utmost importance, such as medical facilities and construction sites. Negative pressure is created by the machine, which helps to isolate contaminated areas and prevent the spread of pathogens.

One of the key components in these machines is the HEPA (High-Efficiency Particulate Air) filter. HEPA filters are designed to trap microscopic particles, including dust, pollen, mold spores, and even bacteria and viruses. These filters have a high filtration efficiency of 99.97%, meaning they can capture particles as small as 0.3 microns in size. This makes them highly effective in removing harmful contaminants from the air.

When negative air machines create negative pressure, they ensure that contaminated air flows into the machine and is filtered through the HEPA filter. The clean air is then released back into the environment, significantly improving the air quality. This process helps to protect the health and safety of individuals in the vicinity, reducing the risk of airborne diseases and allergies.

Negative air machines are also essential in smoke remediation. In the event of a fire, these machines can effectively remove smoke particles and gases from the air, improving the air quality and making the environment safe for occupants. Their ability to quickly and efficiently filter the air helps to minimize the impact of smoke damage in affected areas.

Benefits of Negative Pressure and HEPA Filtration in Negative Air Machines:

- Creates a controlled environment by isolating contaminated areas

- Removes airborne contaminants, including dust, pollen, mold spores, bacteria, and viruses

- Improves air quality and reduces the risk of airborne diseases and allergies

- Efficiently filters smoke particles and gases during smoke remediation

- Provides a healthier and safer environment for occupants

Overall, negative pressure and HEPA filtration are integral components of negative air machines. These machines are crucial for maintaining clean and safe environments, and their use is essential in a wide range of settings. By harnessing the power of negative pressure and HEPA filtration, negative air machines effectively remove airborne contaminants, improving the overall air quality and safeguarding the health and well-being of individuals.

Understanding Air Scrubbers and Negative Air Machines

Air scrubbers and negative air machines serve a similar purpose, but they differ in their design and usage. These machines are essential for maintaining air quality and removing pollutants in various settings. While negative air machines are commonly used in larger spaces such as medical facilities, factories, and construction sites, air scrubbers are more suitable for smaller spaces like residences and restaurants.

Negative air machines work by creating negative air pressure, which helps to isolate spaces and prevent the spread of pathogens. They utilize filters, such as HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air), to effectively clean the air and remove particles. The machines can be configured to exhaust air to corridors, outside, or return air grills, depending on the specific requirements of the space. Proper room sealing and electronic pressure monitoring are crucial for ensuring effective isolation.

On the other hand, air scrubbers are compact devices that focus on air purification and odor control. They utilize advanced filtration systems to remove a wide range of contaminants, including dust, allergens, mold spores, and odors. Air scrubbers are commonly used in residential settings, restaurants, and other smaller spaces where air quality is a concern.

| Negative Air Machines | Air Scrubbers |

|---|---|

| Used in larger spaces | Used in smaller spaces |

| Create negative air pressure | Focused on air purification and odor control |

| Utilize HEPA and ULPA filters | Utilize advanced filtration systems |

| Isolate spaces and prevent pathogen spread | Remove a wide range of contaminants |

Both air scrubbers and negative air machines play a crucial role in removing air pollutants and improving indoor air quality. Whether it’s the larger-scale application of negative air machines in medical facilities or the compact design of air scrubbers for residential use, these machines effectively enhance the air we breathe and contribute to a healthier environment.

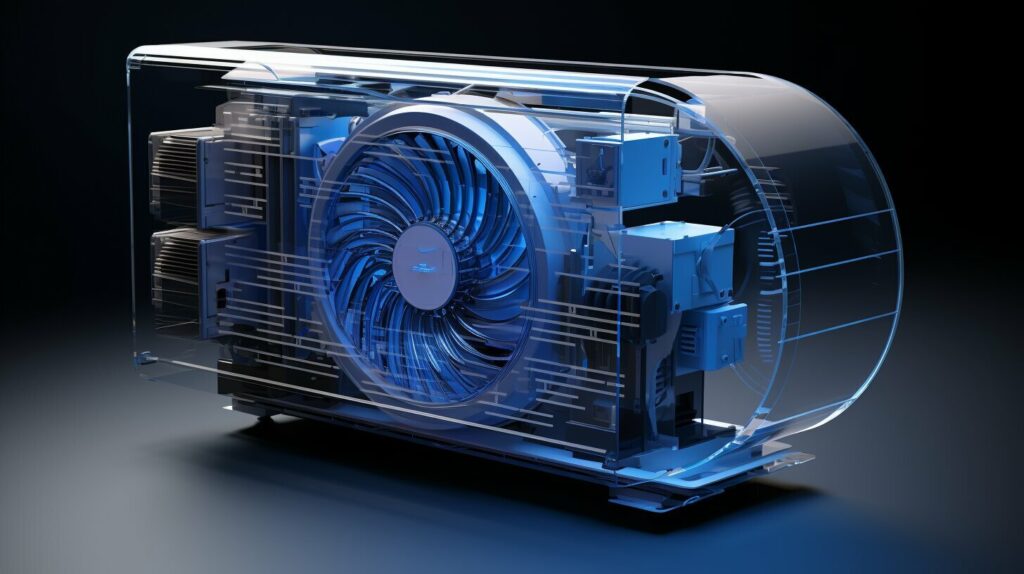

Disclaimer: The image above is for illustrative purposes only and does not represent any specific brand or model of negative air machines.

The Role of Negative Air Machines in Remediation

Negative air machines are specially designed for effective remediation, with superior HEPA air scrubbing performance. These machines play a crucial role in removing harmful contaminants from the air, creating a healthier and safer environment. Whether it’s smoke remediation, mold remediation, or addressing other air quality issues, negative air machines are essential tools in the remediation process.

One of the key features of negative air machines is their ability to create negative pressure within a space. This negative pressure helps isolate the area being remediated, preventing the spread of contaminants to other parts of the building. By creating this negative pressure, the machines effectively trap and remove particles, gases, and odors, improving air quality.

To achieve optimal air scrubbing performance, negative air machines utilize HEPA filters. These high-efficiency filters effectively capture particles as small as 0.3 microns, including dust, allergens, mold spores, and other airborne pollutants. The HEPA filters in negative air machines are designed to meet strict standards, ensuring maximum filtration efficiency and trapping a high percentage of contaminants.

| Key Features of Negative Air Machines |

|---|

| Creates negative pressure to isolate spaces |

| Removes particles, gases, and odors |

| Utilizes HEPA filters for optimal air scrubbing performance |

In addition to their remediation capabilities, negative air machines can also be used for other purposes such as creating a clean and controlled environment in medical facilities or construction sites. They are versatile tools that address a wide range of air quality concerns in different industries.

Overall, negative air machines are a vital component in remediation processes. Their specifically designed functionality, coupled with their superior HEPA air scrubbing performance, ensures the removal of harmful contaminants from the air, promoting health and safety. Whether used in smoke remediation, mold remediation, or other applications, these machines are essential for maintaining a clean and healthy indoor environment.

Exploring the Benefits and Features of Negative Air Machines

The new Aeroclean 600ev negative air unit exemplifies the benefits and features that make negative air machines a wise choice. With its advanced technology and energy-efficient design, this machine is at the forefront of improving air quality in various settings. Whether you need it for medical facilities, factories, or construction sites, the Aeroclean 600ev delivers comprehensive air cleaning capabilities.

One of the key benefits of the Aeroclean 600ev is its powerful HEPA filtration system. This high-efficiency particulate air filter effectively captures particles as small as 0.3 microns, including dust, allergens, and even some bacteria. With its superior filtration performance, the Aeroclean 600ev ensures that the air you breathe is clean and free from harmful contaminants.

The machine’s portability is another notable feature. Designed for ease of use and mobility, the Aeroclean 600ev can be effortlessly moved from one area to another, allowing you to target specific spaces that require air purification. Its compact size and lightweight construction make it suitable for both indoor and outdoor use.

In addition to its filtration and portability, the Aeroclean 600ev also boasts an alarm system that alerts you when the filters need to be replaced. This feature ensures that the machine maintains optimal performance and continues to provide clean air. Furthermore, its lower pressure option allows for quieter operation, making it suitable for environments where noise control is essential.

The benefits and features of the new Aeroclean 600ev negative air unit make it an excellent choice for anyone seeking to improve air quality. Its advanced technology, HEPA filtration, portability, and convenient alarm system set it apart from other negative air machines. Whether you’re dealing with air pollutants in a medical facility or seeking smoke remediation in a residential setting, the Aeroclean 600ev is a reliable and efficient solution.

| Benefits | Features |

|---|---|

| Advanced technology | HEPA filtration |

| Energy-efficient | Portability |

| Alarm system | Lower pressure option |

The Importance of Exhaust Air and Filtration Efficiency

Exhaust air and filtration efficiency are crucial factors in ensuring that negative air machines effectively clean the air. These machines are designed to create negative air pressure, which prevents the spread of contaminants and pathogens in various settings, including medical facilities, factories, and construction sites. By generating negative pressure, the machines isolate spaces and direct airflow towards the filtration system, effectively removing harmful particles and gases from the air.

The filtration system plays a vital role in the cleaning process. Negative air machines utilize advanced filters, such as HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters, to capture and trap particles as small as 0.3 microns. The efficiency of these filters ensures that even the tiniest contaminants, including allergens, mold spores, and bacteria, are effectively removed from the air.

To maximize the effectiveness of negative air machines, proper configuration and exhaust air handling are essential. These machines can be configured to exhaust air to corridors, outside areas, or return air grills. This strategic handling of exhaust air helps maintain a clean and healthy environment by preventing the recirculation of contaminated air. Additionally, proper room sealing and electronic pressure monitoring ensure effective isolation and control of airflows in a given space.

In summary, negative air machines, with their focus on exhaust air and filtration efficiency, are indispensable tools for improving air quality. They provide effective cleaning and removal of harmful particles and gases, creating a healthier and safer environment in medical facilities, factories, and construction sites. By utilizing advanced filters and strategic exhaust air handling, these machines play a crucial role in maintaining clean air and preventing the spread of contaminants.

The Applications and Industries That Utilize Negative Air Machines

Negative air machines find applications in a wide range of industries, from medical facilities to factories, where they combat airborne contaminants, pollutants, and odors. These powerful machines play a crucial role in maintaining a clean and healthy indoor environment, protecting both workers and occupants from potential health risks. Let’s explore some of the key industries and settings where negative air machines are commonly utilized:

Medical Facilities

In hospitals, clinics, and other healthcare settings, maintaining high air quality is of utmost importance. Negative air machines are used to create negative pressure in isolation rooms, preventing the spread of airborne pathogens such as viruses and bacteria. These machines ensure that contaminants are effectively captured and filtered, helping to maintain a sterile environment for patients and healthcare workers.

Manufacturing and Industrial Settings

In factories and manufacturing facilities, airborne contaminants and pollutants are often a byproduct of production processes. Negative air machines are employed to effectively remove these harmful particles, ensuring cleaner air for workers and minimizing the risk of respiratory issues. These machines prove particularly beneficial in industries involving chemicals, painting, welding, and other activities that generate airborne pollutants.

Construction Sites

Construction sites are prone to various airborne pollutants, such as dust, mold spores, and volatile organic compounds (VOCs). Negative air machines are commonly used to control and mitigate these contaminants, improving air quality for workers and nearby residents. By creating negative pressure, these machines help contain the pollutants within construction zones, reducing their impact on the surrounding environment.

In addition to these industries, negative air machines also find applications in laboratories, cleanrooms, data centers, hospitality settings, and residential buildings. They are versatile tools that effectively remove airborne contaminants, ensuring a safer and healthier environment for all.

| Benefits of Negative Air Machines | Features |

|---|---|

|

|

“Negative air machines play a vital role in maintaining air quality in various industries, from healthcare to manufacturing. They are essential tools for creating a safe and healthy environment, protecting workers and occupants from the harmful effects of airborne contaminants.”

Understanding the Technical Specifications and Features of Negative Air Machines

Understanding the technical specifications and features of negative air machines is essential for making an informed decision when it comes to improving air quality. Several factors need to be considered, including particle size filtration, airflow, and specific models like the Abatement Technologies PAS2400.

Particle size filtration is an important aspect to consider in negative air machines. These machines are designed to capture and remove particles of various sizes from the air, including those as small as 0.3 microns. The ability to filter out such small particles ensures that the air being circulated is clean and free from harmful contaminants.

Airflow is another crucial factor to assess. The airflow capacity of a negative air machine determines how quickly it can cycle and clean the air in a given space. Models like the Abatement Technologies PAS2400 offer an airflow capacity of 750 cubic feet per minute (CFM), ensuring efficient and effective air cleaning in larger areas.

When considering specific models, the Abatement Technologies PAS2400 stands out for its exceptional filtration efficiency. Equipped with a HEPA filter with a rating of 99.97%, this machine ensures the removal of even the tiniest particles, allergens, and pollutants from the air. Its advanced features, such as electronic pressure monitoring and adjustable airflow control, make it an ideal choice for maintaining a healthy and safe indoor environment.

Technical Specifications of the Abatement Technologies PAS2400:

| Particle Size Filtration | Airflow Capacity | Filtration Efficiency |

|---|---|---|

| 0.3 microns | 750 CFM | 99.97% |

Understanding the technical specifications and features of negative air machines, such as the Abatement Technologies PAS2400, enables you to select the most suitable option for your specific air cleaning needs. Whether it’s for a medical facility, factory, or construction site, investing in a reliable negative air machine ensures a healthier and safer environment for everyone.

The Advancements in Technology and Portability

Modern negative air machines boast advanced technologies, increased portability, and additional features like alarms, lower pressure options, UV sterilization, and highly efficient first-stage filters. These advancements have revolutionized the way air quality is managed and improved in various industries. With the integration of alarms, users are alerted when filter changes or maintenance are required, ensuring optimal performance and reducing downtime.

The availability of lower pressure options in negative air machines allows for better control over airflow in different environments. This feature is especially beneficial when working in sensitive areas where high pressure may cause disturbance or compromise the containment of contaminants.

UV sterilization is another notable advancement in negative air machines. This technology effectively kills microorganisms like bacteria and viruses that may be present in the air. By utilizing UV light, these machines offer an additional layer of protection against harmful pathogens, contributing to a safer and healthier environment.

First-stage filters play a crucial role in the filtration process. They are designed to capture larger particles like dust, pollen, and pet dander, preventing them from reaching the main filtration system. This not only extends the lifespan of HEPA or ULPA filters but also enhances the overall efficiency of the negative air machine. With highly efficient first-stage filters, airborne contaminants are effectively trapped, promoting cleaner air and minimizing health risks.

| Advancements | Description |

|---|---|

| Alarms | Alert users when filter changes or maintenance are required |

| Lower Pressure Options | Better control over airflow in sensitive areas |

| UV Sterilization | Effectively kills microorganisms for a safer environment |

| First-Stage Filters | Captures larger particles, enhancing overall efficiency |

Conclusion

In conclusion, negative air machines and air scrubbers are essential tools in maintaining clean and healthy indoor air quality, with filters like HEPA filters playing a crucial role in capturing harmful particles. These machines are widely used in various settings, including medical facilities, factories, and construction sites, to ensure the air is free from contaminants.

Negative air machines create negative air pressure, isolating spaces and preventing the spread of pathogens. They use filters, such as HEPA and ULPA filters, to effectively clean the air and remove particles. These machines can be configured to exhaust air to corridors, outside, or return air grills, ensuring that the air is properly filtered and purified.

Proper room sealing and electronic pressure monitoring are crucial for the effective isolation of contaminants. Negative air machines are also used for smoke remediation, effectively removing harmful particles and gases from the air. They provide a comprehensive solution for improving air quality in various environments.

Air scrubbers, on the other hand, are more suitable for smaller spaces like residences and restaurants. They are similar to negative air machines in terms of removing air pollutants and improving air quality. Both negative air machines and air scrubbers are highly effective in capturing airborne contaminants and providing a cleaner and healthier indoor environment.